Three-phase electric power

Three-phase electric power is a common method of alternating-currentelectric power generation, transmission, and distribution.[1] It is a type of polyphase system and is the most common method used by electrical grids worldwide to transfer power. It is also used to power large motors and other heavy loads. Athree-phase system is usually more economical than an equivalent single-phase or two-phase system at the samevoltage because it uses less conductor material to transmit electrical power.[2] The three-phase system was independently invented by Galileo Ferraris, Mikhail Dolivo-Dobrovolsky and Nikola Tesla in the late 1880s.

Contents

[hide]Details

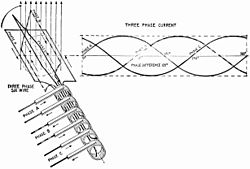

In a three-phase system, three circuit conductors carry three alternating currents (of the same frequency) which reach their instantaneous peak values at one third of a cycle from each other. Taking one current as the reference, the other two currents are delayed in time by one third and two thirds of one cycle of the electric current. This delay between phases has the effect of giving constant power transfer over each cycle of the current and also makes it possible to produce a rotating magnetic field in an electric motor.

Three-phase systems may have a neutral wire. A neutral wire allows the three-phase system to use a higher voltage while still supporting lower-voltage single-phase loads. In high-voltage distribution situations, it is common not to have a neutral wire as the loads can simply be connected between phases (phase-phase connection).

Three-phase has properties that make it very desirable in electric power systems:

- The phase currents tend to cancel out one another, summing to zero in the case of a linear balanced load. This makes it possible to reduce the size of the neutral conductor; all the phase conductors carry the same current and so can be the same size, for a balanced load.

- Power transfer into a linear balanced load is constant, which helps to reduce generator and motor vibrations.

- Three-phase systems can produce a magnetic field that rotates in a specified direction, which simplifies the design of electric motors.

Most household loads are single-phase. In North American single-family dwellings, three-phase power generally does not enter the home; multiple-unit apartment blocks may have three-phase power but three-phase power is not used for household appliances. Utilities that supply three-phase power for lower-load-density area homes typically distribute only one phase to individual loads. Some large European appliances may be powered by three-phase power, such as electric stoves and clothes dryers.

Wiring for the three phases is typically identified by color codes which vary by country. Connection of the phases in the right order is required to ensure correct rotation of three-phase motors. For example, pumps and fans may not work in reverse. Maintaining the identity of phases is required if there is any possibility two sources can be connected at the same time; a direct interconnection between two different phases is a short-circuit.

Generation and distribution

At the power station, an electrical generator converts mechanical power into a set of three AC electric currents, one from each coil (or winding) of the generator. The windings are arranged such that the currents vary sinusoidally at the same frequency but with the peaks and troughs of their wave forms offset to provide three complementary currents with a phase separation of one-third cycle (120° or 2π⁄3 radians). The generator frequency is typically 50 or 60 Hz, varying by country.

Further information: Mains power systems

At the power station, transformerschange the voltage from generators to a level suitable for transmission minimizing losses.

After further voltage conversions in the transmission network, the voltage is finally transformed to the standard utilization before power is supplied to customers.

The majority of automotive alternators produce power as three phase AC power which is rectified to DC through a diode bridge.[5]

Transformer connections

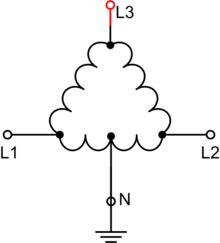

A "delta" connected transformer winding is connected between phases of a three-phase system. A "wye" ("star") transformer connects each winding from a phase wire to a common neutral point.

In an "open delta" or "V" system, only two sets of transformers are used. A closed delta system can operate as an open delta if one of the transformers has failed or needs to be removed.[6] In open delta, each transformer must carry current for its respective phases as well as current for the third phase, therefore capacity is reduced to 87%. With one of three transformers missing and the remaining two at 87% efficiency, the capacity is 58% ((2/3) × 87%).[7][8]

Where a delta-fed system must be grounded for protection from surge voltages, a grounding transformer (usually a zigzag transformer) may be connected to all three phases[according to whom?]; this allows ground fault currents to return from any phase to ground.[according to whom?] Another variation is a "corner grounded" delta system, which is a closed delta that is grounded at one of the junctions of transformers.[9]

Three-wire and four-wire circuits

There are two basic three-phase configurations: delta or wye (star). Either type can be wired for three or four wires. The fourth wire is provided as a neutral. The '3-wire' and '4-wire' designations do not count the ground wire used on many transmission lines which is solely for fault protection and does not deliver power.

A four-wire system with symmetrical voltages between phase and neutral is obtained when the neutral is connected to the "common star point" of an all supply windings. All three phases will have the same magnitude of voltages to the neutral in such a system. Other non-symmetrical systems have been used. In a high-leg deltasystem, one winding of a delta transformer feeding the system is center-tapped. This setup produces three voltages. If the voltage between center tap and the two adjacent phases is 100%, the voltage across any two phases is 200% and neutral to "high leg" is ≈ 173%.[6]

Three-wire distribution systems need one less conductor and help redistribute unbalanced loading during transformation going back to the generation source.[citation needed]

The four-wire wye system is used when ground referenced voltages or the flexibility of more voltage selections are required. Faults on one phase to ground will cause a protection event (fuse or breaker open) locally and not involve other phases or other connected equipment.[citation needed] An example of application is a local distribution in Europe, where each customer is fed a phase and a neutral. When other customers sharing the neutral draw unequal currents, the common neutral wire carries a current as a result of the imbalance. Electrical engineers try to design the system so the loads are balanced as much as possible. By distributing a large number of houses over all three phases, on average a nearly balanced load is seen at the point of supply.[citation needed]

In a three-phase, four-wire, delta (high-leg delta) system, the neutral is a center tap in one of the delta phase supply windings. This can also be supplied by two single-phase transformers in a V formation (open delta).

Single-phase loads

Single-phase loads may be connected to a three-phase system in two ways. Load may be connected across any two phases, or a load can be connected from phase to neutral, if neutral is available.[10]

Single-phase loads should be distributed evenly between the phases of the three-phase system for efficient use of the supply transformer and supply conductors.

In a symmetrical three-phase four-wire, wye system, the three phase conductors have the same voltage to the system neutral. The voltage between line conductors is √3 times the phase conductor to neutral voltage.

- VL-L = √3 VL-N[11]

The currents returning from the customers' premises to the supply transformer all share the neutral wire. If the loads are evenly distributed on all three phases, the sum of the returning currents in the neutral wire is approximately zero. Any unbalanced phase loading on the secondary side of the transformer will use the transformer capacity inefficiently.

If the supply neutral is broken, phase-to-neutral voltage is no longer maintained. Phases with higher relative loading will experience reduced voltage and phases with lower relative loading will experience elevated voltage, up to the phase-to-phase voltage.[citation needed]

A high-leg delta provides phase-to-neutral relationship of VL-L = 2 VL-N , however, L-N load is imposed on one phase.[6] A transformer manufacturer's page suggests that L-N loading to not exceed 5% of transformer capacity.[12]

√3 is ≈ 1.73, so if VL-N was defined as 100%, VL-L would be ≈ 100% × 1.73 = 173% If VL-L was set as 100%, then VL-N ≈ 57.7%

Unbalanced loads

When the currents on the three live wires of a three-phase system are not equal or are not at an exact 120° phase angle, the power-loss is greater than for a perfectly balanced system. The degree of imbalance is expressed by symmetrical components. Three-phase systems are evaluated at generating stations and substations in terms of these three components, of which two are zero in a perfectly balanced system.[citation needed]

Non-linear loads

With linear loads, the neutral only carries the current due to imbalance between the phases. Devices that utilize rectifier-capacitor front-end such as switch-mode power supplies, computers, office equipment and such produce third order harmonics that are in-phase on all the supply phases. Consequently, such harmonic currents add in the neutral which can cause the neutral current to exceed the phase current.[10][13]

Three-phase loads

An important class of three-phase load is the electric motor. A three-phase induction motor has a simple design, inherently high starting torque and high efficiency.[citation needed] Such motors are applied in industry for many applications. A three-phase motor is more compact and less costly than a single-phase motor of the same voltage class and rating and single-phase AC motors above 10 HP (7.5 kW) are uncommon.[citation needed] Three-phase motors also vibrate less and hence last longer than single-phase motors of the same power used under the same conditions.[citation needed]

Line frequency flicker in light can be reduced by evenly spreading three phases across line frequency operated light sources so that illuminated area is provided light from all three phases. The effect of line frequency flicker is detrimental to super slow motion cameras used in sports event broadcasting. Three phase lighting has been applied successfully at the 2008 Beijing Olympics to provide consistent light level for each frame for SSM cameras.[14]Resistance heating loads such as electric boilers or space heating may be connected to three-phase systems. Electric lighting may also be similarly connected.

Rectifiers may use a three-phase source to produce a six-pulse DC output.[15] The output of such rectifiers is much smoother than rectified single phase and, unlike single-phase, does not drop to zero between pulses. Such rectifiers may be used for battery charging, electrolysis processes such as aluminium production or for operation of DC motors.

One example of a three-phase load is the electric arc furnace used in steelmaking and in refining of ores.

In Germany, a 1965 publication shows some "full size" stoves are designed for a three-phase feed. However, the individual heating units may be connected between phase and neutral to allow for connection by three individual circuits on the same single-phase supply.[16]

Phase converters

Phase converters are used when three-phase equipment needs to be operated on a single-phase power source. They are used when three-phase power is not available or cost is not justifiable. Such converters may also allow the frequency to be varied (resynthesis) allowing speed control. Some railway locomotives use a single-phase source to drive three-phase motors fed through an electronic drive.[17]

Mechanical

One method to generate three-phase power from a single-phase source is the rotary phase converter, essentially a three-phase motor with special starting arrangements and power factor correction that produces balanced three-phase voltages. When properly designed, these rotary converters can allow satisfactory operation of a three-phase motor on a single-phase source. In such a device, the energy storage is performed by the mechanical inertia (flywheel effect) of the rotating components. An external flywheel is sometimes found on one or both ends of the shaft.

A three-phase generator can be driven by a single-phase motor. This motor-generator combination can provide a frequency changer function as well as phase conversion, but requires two machines with all their expense and losses. The motor-generator method can also form an uninterruptable power supply when used in conjunction with a large flywheel and a standby generator set.

Non-mechanical

| This section does not cite any references or sources. (December 2012) |

A second method that was popular in the 1940s and 1950s was the transformer method. At that time, capacitors were more expensive than transformers, so an autotransformer was used to apply more power through fewer capacitors. Separated it from another common method, the static converter, as both methods have no moving parts, which separates them from the rotary converters.

Another method often attempted is with a device referred to as a static phase converter. This method of running three-phase equipment is commonly attempted with motor loads though it only supplies 2/3 power and can cause the motor loads to run hot and in some cases overheat. This method does not work when sensitive circuitry is involved such as CNC devices or in induction and rectifier-type loads.

Variable-frequency drives (also known as solid-state inverters) are used to provide precise speed and torque control of three-phase motors. Some models can be powered by a single-phase supply. VFDs work by converting the supply voltage to DC and then converting the DC to a suitable three-phase source for the motor.

Digital phase converters are designed for fixed-frequency operation from a single-phase source. Similar to a variable-frequency drive, they use a microprocessor to control solid-state power switching components to maintain balanced three-phase voltages.

Alternatives to three-phase

- Split-phase electric power is used when three-phase power is not available and allows double the normal utilization voltage to be supplied for high-power loads.

- Two-phase electric power, like three-phase, gives constant power transfer to a linear load. For loads that connect each phase to neutral, assuming the load is the same power draw, the two-wire system has a neutral current that is greater than neutral current in a three-phase system. Also motors are not entirely linear, which means that despite the theory, motors running on three-phase tend to run smoother than those on two-phase. The generators in the Adams Power Plant at Niagara Falls that were installed in 1895 were the largest generators in the world at the time and were two-phase machines. True two-phase power distribution is basically obsolete. Special-purpose systems may use a two-phase system for control. Two-phase power may be obtained from a three-phase system (or vice versa) using an arrangement oftransformers called a Scott-T transformer, invented by Charles F. Scott.[18]

- Monocyclic power was a name for an asymmetrical modified two-phase power system used by General Electric around 1897, championed by Charles Proteus Steinmetz and Elihu Thomson. This system was devised to avoid patent infringement. In this system, a generator was wound with a full-voltage single-phase winding intended for lighting loads and with a small fraction (usually 1/4 of the line voltage) winding that produced a voltage in quadrature with the main windings. The intention was to use this "power wire" additional winding to provide starting torque for induction motors, with the main winding providing power for lighting loads. After the expiration of the Westinghouse patents on symmetrical two-phase and three-phase power distribution systems, the monocyclic system fell out of use; it was difficult to analyze and did not last long enough for satisfactory energy metering to be developed.

- High-phase-order systems for power transmission have been built and tested. Such transmission lines typically would use six phases or twelve phases. High-phase-order transmission lines allow transfer of slightly less than proportionately higher power through a given volume without the expense of a high-voltage direct current (HVDC) converter at each end of the line. However, they require correspondingly more pieces of equipment.

Color codes

See also: Electrical wiring#Color code

Conductors of a three-phase system are usually identified by a color code, to allow for balanced loading and to assure the correct phase rotation for induction motors. Colors used may adhere to International Standard IEC 60446, older standards or to no standard at all and may vary even within a single installation. For example, in the U.S. and Canada, different color codes are used for grounded (earthed) and ungrounded systems.

| Country | L1 | L2 | L3 | Neutral | Ground / protective earth |

|---|---|---|---|---|---|

| Australia and New Zealand as per AS/NZS 3000:2007 Figure 3.2 (or as per IEC 60446 as approved by AS:3000) | Red (or brown)[note 1] | White (or black)[note 1](prev. yellow) | Dark blue (or grey)[note 1] | Black (or blue)[note 1] | Green/yellow striped (green on very old installations) |

| Canada (mandatory)[19] | Red | Black | Blue | White or Grey | Green or bare copper |

| Canada (isolated three-phase installations)[20] | Orange | Brown | Yellow | White | Green |

| European Union and all countries who use European CENELEC standards April 2004 (IEC 60446), Hong Kong from July 2007, Singapore from March 2009 | Brown | Black | Grey | Blue | Green/yellow striped[note 2] |

| Older European (IEC 60446, varies by country[note 3] | Black or brown or grey | Black or brown or grey | Black or brown or grey | Blue | Green/yellow striped[note 3] |

| UK until April 2006, Hong Kong until April 2009, South Africa, Malaysia, Singapore until February 2011 | Red | Yellow | Blue | Black | Green/yellow striped (green on installations before c. 1970) |

| India and Pakistan | Red | Yellow | Blue | Black | Green/yellow striped, or green |

| Former USSR (Russia, Ukraine, Kazakhstan) and People's Republic of China (per GB 50303-2002 Section 15.2.2) | Yellow | Green | Red | Sky blue | Green/yellow striped |

| Norway | Black | White/Grey | Brown | Blue | Yellow/green striped, older may be only yellow or bare copper |

| United States (common practice)[note 4] | Black | Red | Blue | White, or grey | Green, green/yellow striped,[note 5]or a bare copper wire |

| United States (alternative practice)[note 6] | Brown | Orange (delta), violet (wye) | Yellow | Grey, or white | Green |

No comments:

Post a Comment